The overarching aim of this research is to explore novel Machine Learning (ML) techniques and develop toolkits for robust, resilient and transferable Cyber Manufacturing Systems (CMS). The outputs will stimulate effective adoption and integration of Artificial Intelligence and Machine Learning, in production processes and supply chain, as a means to increase productivity in the manufacturing sector by optimising manufacturing processes (improving accuracy, efficiency and cutting cost, high products customisation).

Investigating Machine Learning

This research aims to develop toolkits for robust, resilient and transferable Cyber Manufacturing Systems (CMS).

Background

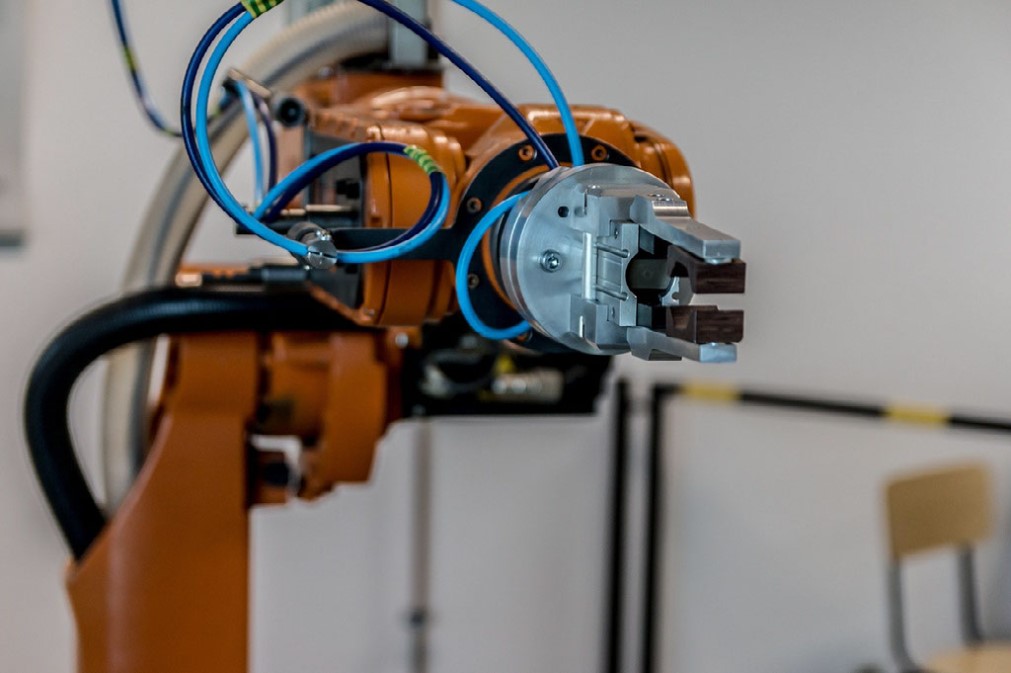

Digital Manufacturing relies on pervasive and ubiquitous use of Information and Communication Technology (ICT), sensors, intelligent robots to deliver the next generation of intelligent, co-operating and interconnected manufacturing systems. The research is aimed to improve techniques that can be used to develop digitalised manufacturing systems to reduce existing inefficiencies in production processes that impact on production costs, unplanned downtime, quality and yields. This is not only detrimental to manufacturing businesses but has a negative impact on the UK Economy. The current productivity levels of UK manufacturers and suppliers is lagging behind global competitors and prevents the UK from successfully competing with other countries in the manufacturing domain - which is vital to keep businesses and jobs in the UK rather than relocate production abroad.

The UK Government wants to increase the strength of the UK Manufacturing Sector. A key means of doing this is the widespread adoption of industrial digital technologies (IDT). Cyber Manufacturing Systems (CMS) are the building blocks of digitalised manufacturing and generate vast amount of data that can be used for real time decision making to achieve optimised performance through predictive and prescriptive analytics. The latter are techniques that use, combine and analyse available data to develop computational models that can predict future outcomes and determine the best course of action. The research, under the fellowship, solves some of the existing problems in this area (CMS), developing new techniques and resources for predictive and prescriptive analytics with the potential to increase efficiency, accuracy and productivity of manufacturing processes. Businesses are therefore more likely to adopt IDTs and improve profitability and sustainability and provide high-quality jobs in a thriving part of the economy.

Aims & Objectives

This project studies novel and robust data analytics methods that enable us to build predictive models that take into account uncertainty, complexity and dynamic behaviour of productions systems.

The project involves:

- Objective 1 - developing algorithms that can reuse previously acquired data/knowledge to build more accurate predictive models that work well in the presence of noise (i.e. 'robust'), are able to adapt to changes over time (i.e. 'resilient') and can be scaled up across multiple factories (i.e. 'transferable').

- Objective 2 - developing and testing novel non-parametric methods for estimation of uncertainty and risks associated to a decision to enable real time mission and safety critical decision making (both automated and human driven) based on predictions.

- Objective 3 - iteratively developing, deploying and testing predictive and prescriptive models in real and simulated industrial scenarios to obtain acceptable level of performance, usability and robustness.

Our industrial collaborators are Crown Holdings, TATA Steel, Sony and Vortex IoT - they are providing labelled and aggregated datasets for testing the methods through computer simulations and enabling feasibility studies to be conducted in factory environments.

The outcomes of the research are ultimately to improve the quality of products, achieving less wastage and unnecessary costs. Through increased adoption of IDTs, the production of goods will, importantly, be more efficient, reliable and profitable. This will support the regeneration of the Manufacturing Sector and boost the global competitiveness of the UK.

The project is funded through Engineering and Physical Sciences Research Council.

Three interacting work packages have the following objectives: