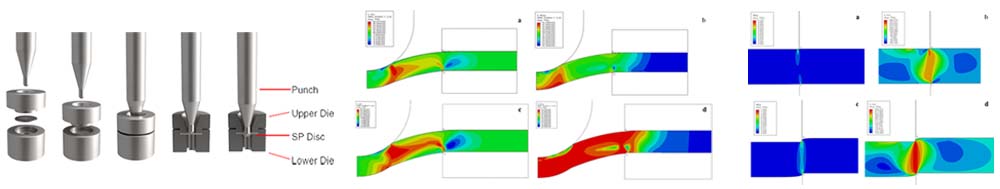

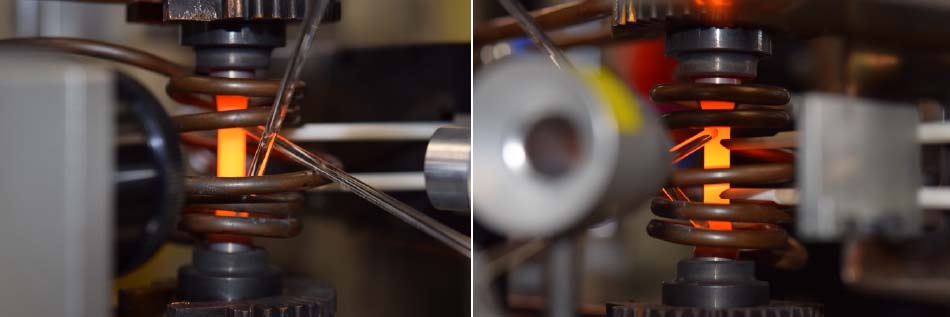

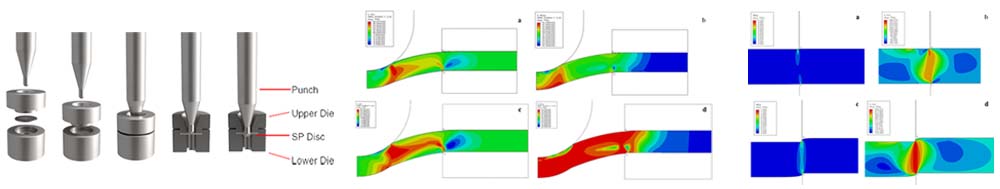

The Small Punch (SP) and Shear Punch (ShP) tests are well established mechanical test approaches that have found application in several industrial sectors for material ranking and mechanical property estimation, particularly where more conventional approaches are inhibited. Such methods are receiving increased attention from engineers who recognise the significant cost benefits that these test methodologies have to offer in terms of far less material wastage for specimen manufacture. In addition, test specimens for SP and ShP experiments can be extracted from larger components to determine a localised distribution of properties or for remnant life assessment of service parts, benefits that may be restricted when looking to employ larger scale test pieces.

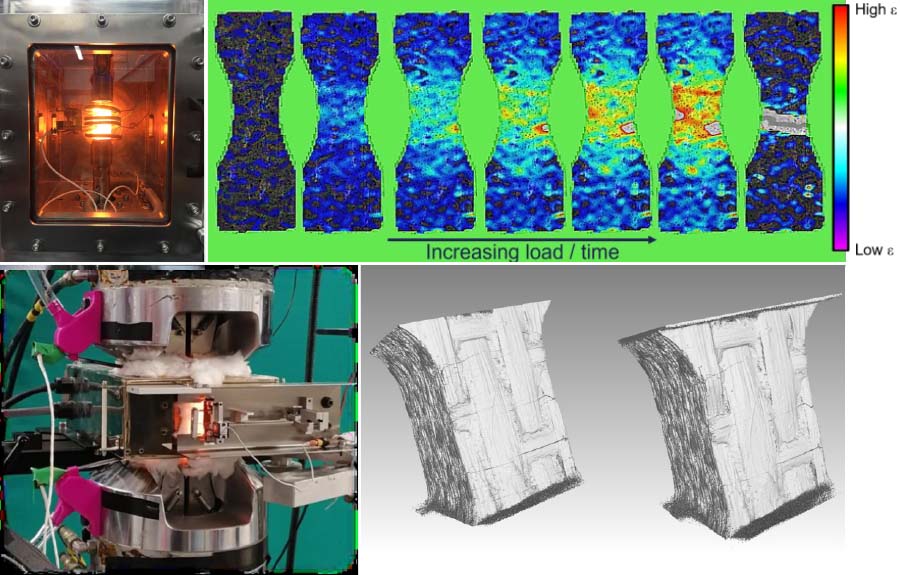

The team in the ISM were some of the key contributors to the standardisation of the SP test, which was standardised by ISO and ASTM in 2020. The test method can be used to obtain creep rupture lives and tensile fracture data for a wide variety of different material systems. More recently fatigue live estimations have been approximated from the test, enabling a new collection of researchers to adopt such test methodologies. Indeed, the number of publications relating to small scale testing research is increasing every year, with numerous worldwide laboratories now utilising the SP test for material characterisation for all manner of purposes.

Key Publications:

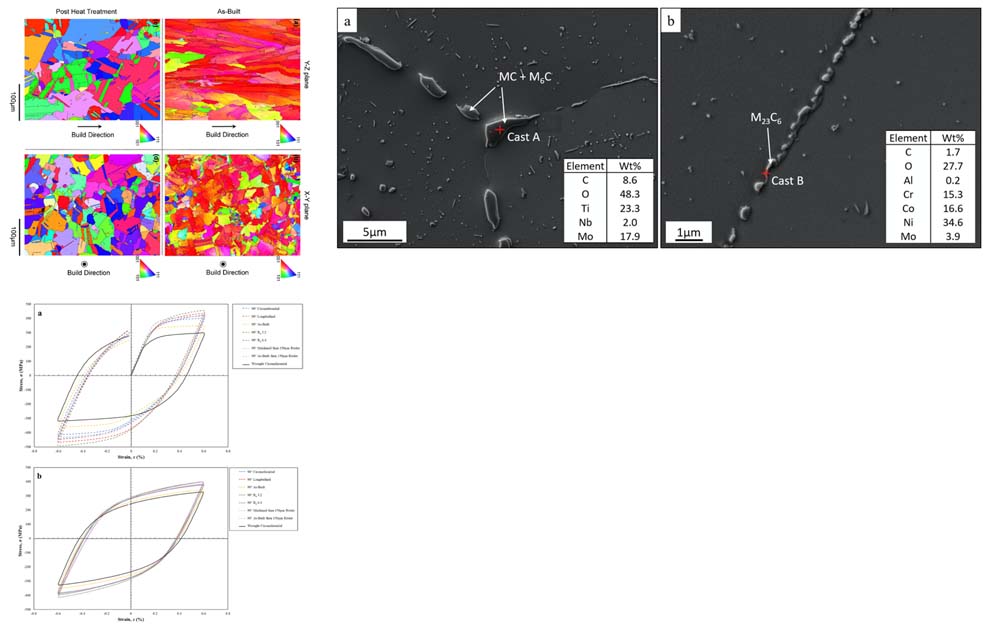

Evaluating the efficacy of alternative small scale test methodologies in deriving the mechanical properties of additive manufactured materials. Lancaster, R.J., Barnard, N.C., Haigh, B., Sackett, E., May, P.E., Douglas, R., Britton, D., Jeffs, S.P. Journal of Materials Research and Technology, 2023, 26, pp. 9328–9345

Investigation of the strain rate sensitivity of CoCrFeMnNiTix (x = 0, 0.3) high-entropy alloys using the shear punch test. González, S., Sfikas,. A.K., Kamnis, S., John, S.E., Barnard, N.C., Gammer, C., Eckert J., Garay-Reyes C.G., Martínez-Sánchez R.,Naung S.W., Rahmati M., Keil T., Durst, K., Lancaster, R.J. Materials and Design, 2023, 233, 112294

Computational and experimental investigation of the strain rate sensitivity of small punch testing of the high-entropy alloy CoCrFeMnNi. González, S., Sfikas, A.K., Kamnis, S., John S.E., Nye Z.W., Spink M., Allen C., Martínez-Sánchez R., Naung S.W., Rahmati M., Keil T., Durst K., Lancaster R.J. Journal of Alloys and Compounds, 2023, 936, 168219

Derivation of material properties using small punch and shear punch test methods. Lancaster, R.J., Jeffs, S.P., Haigh, B.J., Barnard, N.C. Materials and Design, 2022,215

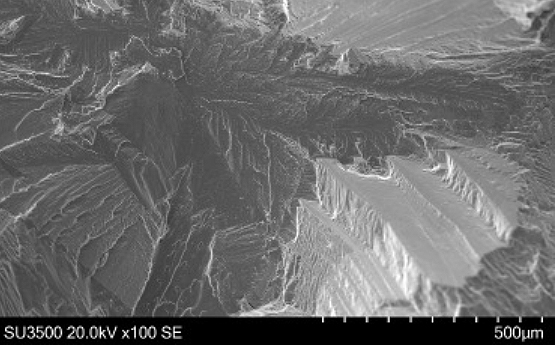

Characterising the fatigue performance of additive materials using the small punch test. Lewis, D.T.S., Lancaster, R.J., Jeffs, S.P., Illsley, H.W., Davies, S.J., Baxter, G.J. Materials Science & Engineering A, 2019, 754, 719-727

Development of a novel methodology to study fatigue properties using the small punch test. Lancaster, R.J., Jeffs, S.P., Illsley, H.W., Agryakis, C., Hurst, R.C., Baxter, G.J. Materials Science & Engineering A, 2019, 748, 21-29

Creep strength and minimum strain rate estimation from Small Punch Creep tests. Holmström S., Li Y., Dymacek P., Vacchieri E., Jeffs S.P., Lancaster R.J., Omacht D., Kubon Z., Anelli E., Rantala J., Tonti A., Komazaki S. Materials Science & Engineering A, 2018, 731, 161-172

The contribution of small punch testing towards the development of materials for aero-engine applications. Hurst, R.C., Lancaster, R.J., Jeffs, S.P., Bache, M.R. Theoretical and Applied Fracture Mechanics, 2016, 86, 69-77

An analysis of small punch creep behaviour in the γ titanium aluminide Ti-45Al-2Mn-2Nb. Lancaster, R.J., Harrison, W.J., Norton, G. Materials Science & Engineering A, 2015, 626, 263-274

Creep lifing methodologies applied to a single crystal superalloy by use of small scale test techniques. Jeffs, S.P., Lancaster, R.J., Garcia, T.E. Materials Science & Engineering A, 2015, 636, 529-535